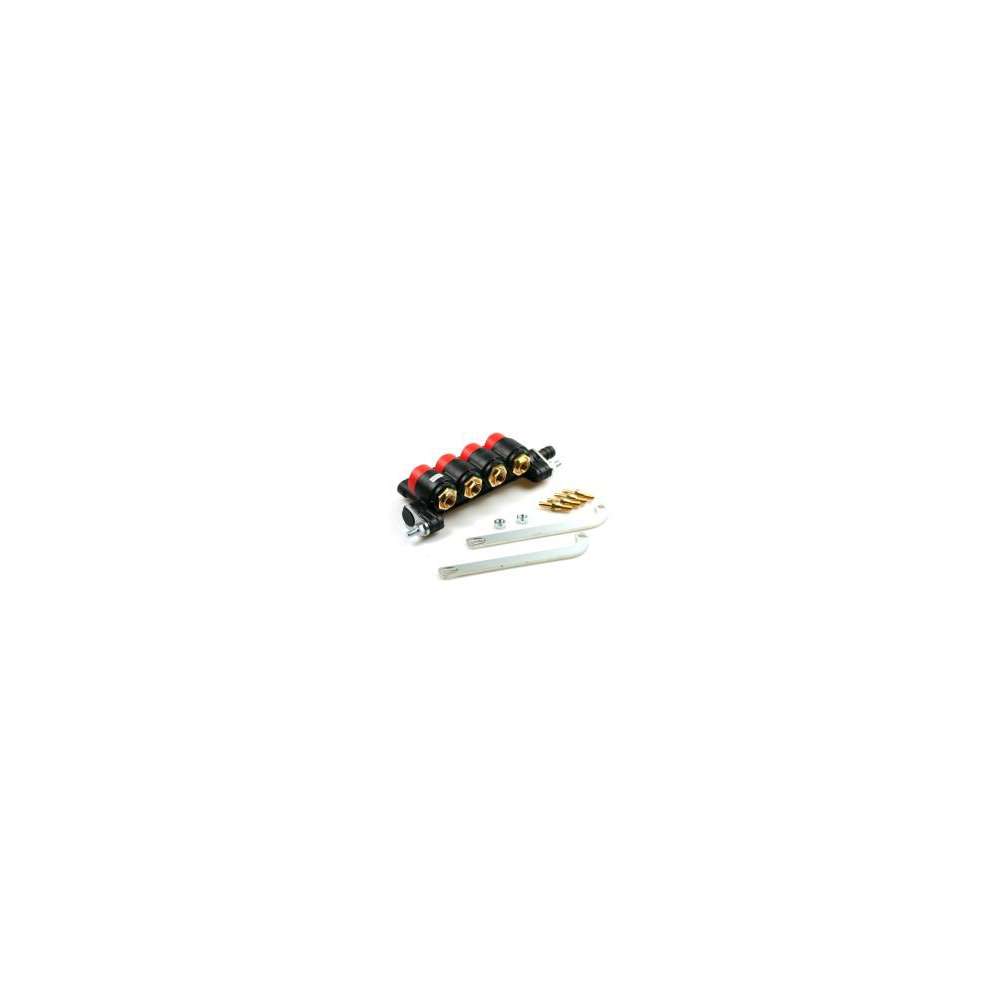

LPG Injector Rail EMER Valtek Type 34 - 4 injectors

NO LONGER AVAILABLE

Homologation number: E4-67R-010196 - E4-110R-000122

Excluding injector outputs.

Foreign companies with a valid VAT number shop VAT-free here! READ HOW.

Shipping& Delivery

Shipping& DeliveryDiscount on Shipping from €150,- and extra discount from €250,-

Safe & Trusted

Safe & TrustedWebshop Trustmark Certified Member & Secured by SSL.

TÜV ISO 9001

TÜV ISO 9001Certified by TÜV Nord Netherlands

Refund policy

Refund policy14-Day Reflection Period & Return Policy

LPG Injector rail EMER Valtek Type 34 - 4 injectors

Homologation number: E4-67R-010196 - E4-110R-000122

(PLEASE NOTE! This is an approval number and may be valid for a series of products / family. This is therefore NOT a type number! !!Check carefully the Model Code / Type Number / Size of the desired product.)

Excluding injector outputs.

Including temperature sensor

TIP! Replace the drying gas filter in a timely and regular manner:

An average drying gas filter lasts up to 20,000 km. Preferably replace the filter sooner.

This replacement period applies to an average engine capacity of approximately 1.8L. Larger engines use more gas, which means the gas filter also needs to be replaced sooner.

It may also be that during some refuelings the LPG contains a lot of contamination (with oil and grease), making it necessary to replace the filter earlier. Please take this into account.

Replacing/cleaning the gas filter in a timely manner is necessary to prevent contamination of the gas system and gas injectors.

Background information regarding problems with gas injectors:

In most cases, the problem is caused by the injectors being contaminated with paraffin (oils and fats from the LPG). The filter in front of the injectors must ensure that the injectors do not become dirty quickly. This filter eventually becomes saturated and must be replaced in a timely manner. If the filter is not replaced, the paraffin will no longer be captured and will end up in the injectors.

It is not the case that the injectors will leak or no longer open. But the opening and closing times are no longer correct. The injectors remain open longer than they should (during dynamic behavior), causing too much fuel to be dispensed. (too rich mixture = high CO)

The injectors will then deviate, especially with short injection times (low engine load). The engine will run cluttered and there will be excessive differences between the injectors. Cleaning the injectors is often pointless, because there has often been too much wear in the injector, which means that the guide of the plunger (sealing disk) no longer has the correct fit. The plunger no longer moves up and down smoothly, but does so in a stuttering and wobbling manner.

If the injectors are replaced without replacing the filter, the new injectors will also quickly become dirty again. (read symptom relief, not a long-term solution)

Data sheet

- Right of Withdrawal

- WARNING! The right of withdrawal does not apply to electronic components. Returns or exchanges are NOT possible.

- Downloads:

- Manuals and Documentation - See the tab Attachments on this page.

- Related Products:

- See bottom of this page

- Shipping Costs:

- Is calculated in the Checkout and is visible there. (Depends on total weight, destination and discounts.)

No customer reviews for the moment.