What does an LPG Evaporator do and how does it work?

In this article we explain how an LPG Evaporator (also sometimes called a clock) works in general and how it should be used and connected. This article is universal and therefore not specific to a particular type or model. Here we try to cover the most important information that applies to almost all LPG evaporators. We distinguish between two groups / types of evaporators; A: LPG Evaporators for traditional LPG systems with a mixer or mixing piece and B: LPG Evaporators for Vapor Gas Injection.

The basic function of an LPG evaporator is to evaporate the LPG that comes in liquid form from the LPG tank and flows into the evaporator and regulate it to a working pressure that is suitable for the rest of the LPG system. For traditional gas systems, this pressure is approximately equal to the air pressure and the evaporator must be adjusted to the suction force of the mixing piece or the gas mixer. (more on this later). For vapor gas systems, the operating pressure is usually somewhere between 0.8 bar to 1.5 bar gauge pressure (relative to the inlet manifold pressure MAP). 1.0 bar overpressure is pretty much the standard.

Heat energy and good heat exchange are required to evaporate LPG. For this reason, the warm coolant from the engine is used to flow through the evaporator and thus transfer its heat to the aluminum of the evaporator (Aluminium is a good heat conductor). On the other side of the aluminum of the evaporator, the liquid LPG enters and comes into contact with the heat aluminum and is given space to expand, causing the gas to evaporate. For vapor gas injection systems, the operating pressure is higher than with traditional systems and therefore more heat energy is required to evaporate the gas. Therefore, with vapor gas injection it is necessary that the engine is sufficiently warm (30 - 40 degrees) to be able to drive on LPG.

How does the internal construction of a Traditional LPG Evaporator work?

A construction of a membrane, a valve and a spring ensures that the gas flow is adjusted depending on the suction power. If the spring pressure (adjustable) increases, the diaphragm will move outwards and the valve (which is connected to the diaphragm) will close. The spring presses against the siphon of the valve and therefore closes the valve, causing less gas to leave the evaporator. The force with which this spring presses the valve closed can be adjusted using an adjustment screw. The higher this force, the more suction power is required to open the valve. Correct adjustment of the spring pressure is crucial, because the evaporator must work in harmony with the suction force of the mixing piece / gas mixer and must therefore be adjusted accordingly. The main diaphragms of traditional evaporators are large to have a large surface area and are therefore very sensitive to the suction force from the mixing piece.

How does the internal construction work in a Vapor Gas Injection Evaporator?

A construction of a membrane, a valve and a spring ensures that the pressure is adjusted. As the pressure increases in the gas chamber, the diaphragm will move outwards and the valve (which is connected to the diaphragm) will close. A spring on the outside of the membrane pushes the membrane inward again. The force exerted by this spring can often be adjusted using an adjustment screw. The higher this force, the higher the gas pressure on the inside of the membrane. The gas pressure on the one hand and the spring pressure on the other are therefore equal, bringing the membrane into a state of equilibrium. For example, if gas is taken from the evaporator to the engine, the pressure will drop and the spring pressure will prevail over the gas pressure, causing the diaphragm to move inwards and the valve to open (further). New gas flows in, evaporates and causes the pressure to rise again, creating an equilibrium situation again.

What connections and adjustment screws are there on an LPG Evaporator?

All LPG evaporators have virtually the same / comparable connections. These are the LPG inlet, gas outlet, water connections, mounting point(s) and adjustment screws. these are usually also indicated on the evaporator itself with terms such as "Gas in", "Gas Out", "Water"

Below we will discuss and explain each of these components separately.

Example images of a Landi Li02 Evaporator

Legend:

1) LPG inlet and connection for LPG gas valve. (M10 thread)

2) LPG outlet (Hose barb)

3) Output pressure adjustment (increase or decrease spring pressure)

4) Vacuum connection (MAP)

5) Pressure relief valve

6) Coolant connections hose barbs Ø16mm

7) Attachment point

LPG Inlet: For safety reasons, it is mandatory that every LPG Evaporator has an LPG Gas shut-off valve at the inlet. In some (more modern) LPG evaporators, this gas valve is already standard or integrated on the evaporator. But in many cases a gas shut-off valve must be installed separately at the inlet of the LPG evaporator. (In our webshop it is indicated for each type of LPG evaporator whether it already has a gas shut-off valve or whether the corresponding gas shut-off valve is indicated.) This gas shut-off valve is an electromagnetic valve that only allows the gas to pass if it is controlled and opened by the LPG system by means of an electric signal. (while driving on LPG) For example, if the engine shuts down or switches back to petrol, the gas valve must close and no LPG can flow into the evaporator.

Most LPG Evaporators have an internal M10x1 threaded connection or if it is a large evaporator for heavy engines, this can also be an M12x1 threaded connection. But there are also evaporators that have a different type of connection at the input. Examples include: Landi Renzo IG1, Prins VSI, IMPCO with 1/4" NPT thread.

Most gas valves also have an internal M10x1 threaded connection at the inlet for a 6mm LPG line, or if it concerns a heavy engine, this is usually an M12x1 threaded connection for an 8mm LPG line for more capacity.

Ensure that the LPG pipe is sufficiently large, so that there is sufficient LPG supply from the LPG tank. Rule of thumb: For engines up to approximately 180 hp, 6mm LPG pipe is used. For heavier engines, 8mm LPG pipe is preferably used. You can find these products in our webshop.

Electric Coil (solenoid valve): Apart from the electric coil on the gas valves on the inlet (as explained above), some evaporators (such as: LOVATO RGE / OMVL R90 / Landi Renzo SE81) also have an additional integrated solenoid valve (Electric Coil) . This coil must be energized (just like the gas valve) when driving on LPG, otherwise no gas will come out of the evaporator. This coil is therefore electrically connected in parallel with the gas valve on the input. (Use a relay to power multiple coils at the same time).

NB! The LOVATO RGV (Vacuum version) also has an Electric Coil, but this is only intended for gas starting. It is a so-called choke coil and only needs to be energized for a short time (a few seconds) so that some gas flows from the evaporator to enable start-up.

LPG Output: The gas outlet of an evaporator is usually equipped with a hose barb to which a gas hose can be connected. A hose clamp over the gas hose ensures that it fits properly. It is important to use the correct internal diameter gas hose for proper mounting and sealing. This is especially important when it comes to vapor gas injection vaporizers, as they provide higher gas pressure than traditional vaporizers. Often a certain brand always uses the same hose barb size on all their vapor gas LPG Evaporators. For example, Landi Renzo uses the size 14mm, BRC usually 12mm and Prins 16mm.

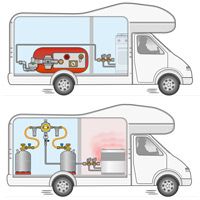

Water connections: Most evaporators use hose barbs with a diameter of 15 / 16 mm to which the coolant hoses are connected. These hose barbs often have an angle of 60 or 90 degrees and can be rotated in the evaporator, so that they can be properly positioned to connect the coolant hoses. In most cases, these car heater hoses have an internal diameter (ID) of 15 / 16 mm and are connected to the engine coolant circuit via T-pieces. (usually parallel to the interior heating). For good flow and ventilation of the evaporator, it is recommended to connect the inflowing coolant to the bottom of the evaporator and the outflowing side to the top. This makes it easier for air to escape from the evaporator.

Vacuum connection (MAP): LPG evaporators for vapor gas injection systems usually have a vacuum connection, also called a MAP connection. This is usually a small hose barb with a diameter of 4 - 6mm, to which a vacuum hose is connected, which at the other end is connected to the intake manifold and thus provides the pressure / vacuum of the intake manifold (Manifold Absolute Pressure). This hose barb is located somewhere on the front cover behind which the diaphragm is located and where the pressure adjustment screw / spring is also located. In this way, two forces are applied to the outside of the membrane; 1: The spring pressure as described earlier and 2: the underpressure from the intake manifold. The aim is to create a gas pressure that has a fixed pressure difference compared to the intake manifold pressure. We also call this a compensated connection with respect to the intake manifold.

This is particularly important for turbo engines where the intake manifold pressure is well above atmospheric pressure. In that case it is important to allow the gas pressure to increase with the intake manifold pressure / turbo pressure / MAP.

NB! Some traditional LPG evaporators also have a vacuum connection (such as the LOVATO RGV). But this is used for a completely different function than described above. This is used on LPG systems where no electrical safety relay is used to control the aforementioned gas valves. Instead, the engine vacuum is used to determine whether the engine is still running and, depending on this, the evaporator should continue to supply gas or shut down. You usually see this applied to, for example, forklift trucks, where the RDW requirements do not apply.

Pressure relief valve: In addition to the MAP connection, some evaporators have another small hose barb connection. However, it is internally connected to the gas chamber (the space on the inside of the membrane). This is a pressure relief valve that, in the event that the pressure becomes too high, will release the gas in order to reduce the pressure. Do not confuse this connection with the previously discussed MAP connection, otherwise the evaporator will not supply the correct gas pressure and the car will run less well on gas. A gas hose must be connected to the pressure relief valve, which is not connected to anything at the other end. This only serves to drain the gas to the outside of the engine compartment. This gas hose usually ends somewhere down in the wind.

Temperature sensor (optional): To determine whether the coolant is warm enough to drive on LPG, a gas system is equipped with a coolant temperature sensor in the form of an NTC (Negative Temperature Coefficient), which is essentially a variable resistance depending on the temperature. This temperature sensor is sometimes mounted in a water hose, but in many cases it is also integrated into the evaporator to directly determine the temperature of the evaporator.

Mounting points: Usually the mounting points (or mounting point) are located on the back cover or on the body of the evaporator. (The pressure adjustment is usually located on the front cover and must therefore remain accessible.) (On the Emer Palladio evaporator, the mounting points are on the front cover, because the gas shut-off valve is positioned on the rear cover. A special mounting bracket is included.)

Drain plug: Traditional LPG evaporators often have a drain plug somewhere at the bottom of the evaporator to drain excess sludge (paraffin). This sludge must be drained over time by removing the drain plug, after the evaporator has first been properly heated by the coolant. Only remove the drain plug when the engine is not running. Collect the sludge with a container.

Vapor gas injection evaporators usually do not have a drain plug, because the pressure in the evaporator is higher.

Adjustment screw: As previously explained in the operation of an evaporator, an evaporator has a diaphragm-valve-spring construction for adjusting the gas pressure. The spring pressure is adjustable on most evaporators, which is necessary for proper adjustment of the gas system. If the spring pressure is increased (on most evaporators by turning the adjustment screw clockwise), the gas pressure will increase or the evaporator will supply more gas. With a Landi Renzo IG1 evaporator the direction of rotation is reversed, but this is usually indicated on the evaporator itself.

Adjusting a traditional LPG evaporator: Correct adjustment is particularly crucial in traditional gas systems where the evaporator must work in harmony with the suction of the mixing piece / gas mixer and must therefore be adjusted accordingly. The main membrane of traditional evaporators are large to have a large surface area and are therefore very sensitive to the suction force from the mixing piece. The exact way in which this should be done may differ slightly per type of evaporator, but basically it comes down to the following.... Read more in the article "Traditional LPG system?"

Adjusting a vapor gas injection LPG evaporator: For gas injection systems, adjusting the gas pressure is also important, but to a lesser extent, because the gas pressure is measured by the gas computer (ECU) and the gas injection times can be adjusted based on the gas pressure. So there is some degree of correction available. But in short you can say that the gas pressure, the gas injector size and the software must be adjusted to each other in such a way that the correct amount of gas can be dosed. The gas pressure and the gas injector size must be sufficient to supply the engine with enough gas at full power. But perhaps even more important (for MOT and pleasant driving behavior) is that the gas pressure and gas injector size are not too high and too large that small doses cannot be accurately administered. Because then the car will idle messily and possibly stall. Proper adjustment is the job of an expert who knows well how an engine management system works and which parameters have an influence.

How do I identify the type of LPG Evaporator?

LPG evaporators contain information such as; make, model, version, approval numbers and LOT/Serial numbers. But how do you recognize what the type number is and what, for example, an approval number is, etc.

To identify your evaporator, it is first important to determine the brand of the product. This is usually printed somewhere or on a sticker. Examples include: Landi Renzo, BRC, OMVL, LOVATO, IMPCO, PRINS

In addition, the type/model and version will also be mentioned on the evaporator. This is important information for identifying your evaporator.

Do not confuse the type/model number with the approval number or production numbers which are also present on the evaporator:

Approval Number: All LPG Parts sold in the EU must have an ECE 67R-01 approval. This is an EU regulation for Automotive LPG parts. Such a number starts with a country code, such as E13 (Italy), which indicates in which country the product is approved. Then the Regulation number "67R-01" Followed by 4 / 5 final numbers and finally the pressure class of the regulation; Class 1 (high pressure up to 30 bar), Class 2 (medium pressure / everything after the evaporator) and Class 3 (low pressure). Example "E8 67R-011618 Class 1". This approval number is often not only specific to one type of evaporator, but may be valid for a family of products, i.e. different variants of the evaporator. So this number does not indicate exactly which version and version / size of the product it concerns. Please note this.

Production numbers: Something about the production is also often indicated on an LPG part, for example with a LOT number / Batch number or a Serial Number (SN), which tells something about when and where the product was produced. This can be important for the traceability of a product. Such a production number is therefore unique for a certain series or specific to that individual product (just like a chassis number of a car, for example). This is often indicated with an abbreviation such as "LOT", "SN"

How do I install an LPG evaporator? And how do I connect this?

When replacing the old evaporator with a new one: Make sure you have properly identified your old evaporator. What is the make, model and version or variant? Take photos of how the evaporator is mounted in the car and how all hoses and plugs are connected before dismantling the old evaporator. This can help you install the new evaporator.

- Respect the guidelines and installation requirements applicable in your country. For the Netherlands, these are the RDW LPG installation requirements.

- Make sure you have the right tools. As a rule, basic garage tools are sufficient.

- Remove any plastic caps from the evaporator before mounting the evaporator.

Position and mounting of the evaporator:

- Mount the evaporator in such a way that it is accessible for maintenance and adjustments.

- Use a support (supplied) to mount the evaporator. And use the intended mounting points of the evaporator for this. (Do not make holes or threads in the evaporator yourself.)

- Under no circumstances mount the evaporator directly on the engine, on components located on the engine or directly on the bodywork.

- Install traditional evaporators with the diaphragm vertical and in the direction of travel of the car. In other words; An evaporator has a round shape, somewhat like a wheel. Mount the evaporator in the same position as a wheel on the car. If it were instead placed perpendicular to the direction of travel, this could have an effect on the position of the membrane and thus influence the mixture when the car brakes or accelerates.

- Mount the evaporator below the highest liquid level of the coolant system to prevent air from entering the evaporator.

LPG Pipe and Gas Hose: Only use gas hoses and LPG pipes that are in good condition and approved.

Copper LPG pipe or plastic LPG pipe with 67R-01 Class 1 approval must be used at the LPG inlet. Make sure you use the correct type of coupling so that the pipe fits the evaporator/gas valve inlet and is connected without leaks.

Use gas hose of the correct internal diameter that corresponds to the diameter of the hose barb on the evaporator. Make sure it is connected leak-free by using a hose clamp. With vapor gas injection evaporators, gas hose with 67R-01 class 2 approval is required on the gas outlet due to overpressure.

Make sure that the LPG Pipe and Gas Hoses:

- cannot rub against other parts, so that no unnecessary wear can occur;

- be secured at sufficient points along the way using pipe brackets and tie-down straps.

- do not kink or be pressed closed.

Water hoses and connections:

- Connect the water hoses leak-free. The water connections on the evaporator are usually rotatable to allow convenient routing of the water hoses.

- Secure the water hoses using hose clamps.

- The other ends of the water hoses are generally connected parallel to the heater hoses using T-pieces.

- Make sure there are no sharp bends in the water hoses. A good and even heat exchange is necessary to evaporate the LPG and to supply sufficient gas.

- Refill the coolant system according to factory instructions. Check the level several times in the days after installation.

- Check the evaporator heating and for any water leakage by running the engine warm.

Post-assembly check: Make sure that all connections are leak-free and check this several times after installation.

- Connection of LPG line to gas valve / LPG evaporator.

- Connection of LPG gas valve to LPG evaporator

- Gas hose at the output of the LPG Evaporator

- Water connections (Coolant)

Adjusting the evaporator: As above in the section about the adjustment screw, it is important to adjust the evaporator. With a Vapor Gas Injection evaporator this may not be necessary if you use a specific version with a certain pressure. Whether adjustment of the pressure is necessary cannot be determined in advance, because this depends on the rest of the system and the software settings. For a traditional evaporator it is almost certain that it must be adjusted to the suction power of the mixing piece / mixer. The adjustment of the evaporator largely determines the mixture of the engine. We explain how to adjust a traditional evaporator in the article "Traditional LPG Systems".

Video LOVATO and OMVL R90

DISCLAIMER

The information in this article is intended as an aid only. No rights can be derived from this article. The applicable laws and regulations (such as the RDW LPG installation requirements or NPR-2577 guideline) are always leading.

Please read our full disclaimer here.

All images are Copyright protected.

Comments

No comment at this time!

Leave your comment